![A customized humanoid robot developed by Tianqi, a Chinese electric vehicle and robot company, with Galbot, a leading Chinese robot company. The humanoid robot is currently being put into production lines of several companies, including Chinese electric vehicle brand Zicker, to handle the work as if it were reflected on a monitor. [Woosh = correspondent Song Kwang-seop]](https://wimg.mk.co.kr/news/cms/202508/25/news-p.v1.20250824.17b46fcc3b604748934210cbdf403e43_P1.png)

«This is a view of checking that the cables in the vehicle are fully installed and that the screws attached to the wheels are tightened properly.»

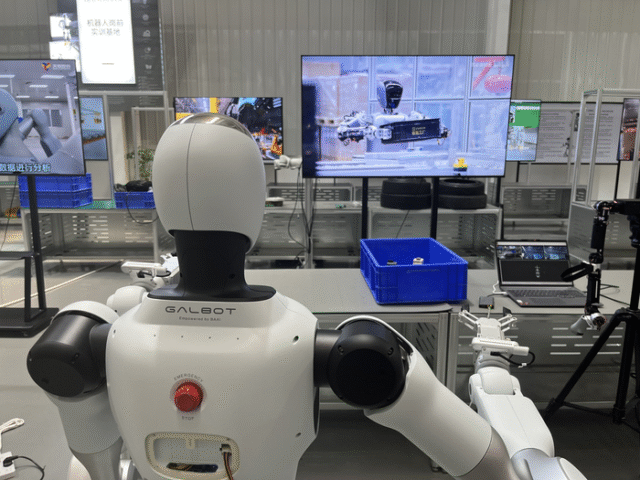

On the 19th, Wang Zhao, head of Shenzhen at Tianqi, an electric vehicle and robot material, parts, and equipment company based in Wuxi, Jiangsu Province, China, said, referring to a humanoid robot looking at every corner of the vehicle in an exhibition hall that has moved its production line. The robot, which approached the wheel with a rod with sensors in both hands, moved both arms up, down, left and right to check whether the wheel was properly installed for about 10 seconds. After confirming that there was no abnormality, he moved to the front of another wheel and repeated the same motion. The robot was developed by Tianqi with Galbot, a Chinese robot company.

![A customized humanoid robot developed by Tianqi, a Chinese electric vehicle and robot company, with Ubitech, a leading Chinese robot company. The robot is put into the production line to check if there is anything wrong with the body. [Woosh = correspondent Song Kwang-seop]](https://wimg.mk.co.kr/news/cms/202508/25/news-p.v1.20250824.7b309308b93f4cd8890b685d9f7b9d68_P1.png)

«Humanoid robots’ ‘carrying goods’ is the most basic movement for industrial robots,» Wang said after showing the humanoid robot’s transportation of goods jointly developed with Chinese robot company Ubitech. «We are focusing on training robots for a more complete job performance.» Tesla has invested a total of 100,000 hours in training humanoid robots ‘Optimus’ to carry goods, he said. «In other words, training is essential for robots to be used on a large scale in industrial sites.»

Founded in 1984, Tianqi started out as an automotive equipment company. At that time, the main business was the installation of conveyor belts in automobile factories. Thanks to the growth of the automobile industry, it was listed on the Shenzhen Stock Exchange in 2004. Since the 2010s, the Chinese electric vehicle market has rapidly expanded and grown into a major electric vehicle small manager company, and over the past decade, it has supplied products to 73 factories of 32 automakers worldwide. China’s Huawei built the M9 plant of the electric vehicle brand «original» in collaboration with electric vehicle startup Ceres.

![Like an athlete, Unitri's "G1" is running vigorously in the 1,500m running event on track and field, which has attracted as much attention as the martial arts event on the 15th. [Beijing = Special correspondent Song Kwang-seop]](https://wimg.mk.co.kr/news/cms/202508/25/news-p.v1.20250818.4687ce1c96564e058f0d59c1b6d5023b_P1.jpg)

Recently, it has become a small robot manager company beyond electric vehicles. This is because it is supplying humanoid robots to production lines to meet customer needs. Although it does not make finished robots by itself, it is conducting joint development with China’s leading humanoid robot companies while manufacturing robot parts. When Ubitech and Galbot make hardware, Tianqi is in charge of software. In particular, it has a strength in entering the information necessary for production into the robot and training based on it. Currently, there are dozens of robots undergoing training.

In this regard, a Tianjin official said, «Many robots conduct training to perform various movements, including automobile parts and battery-related tasks. Through this process, we aim to increase the production efficiency of companies.» The results of robot training are also gradually appearing. Recently, China’s Geely Automobile’s premium electric vehicle brand Zicker plant has introduced its own trained humanoid robot. It did not give an exact number, but it said it had already provided dozens of robots to several companies besides Zicker.

![A customized humanoid robot developed by Tianqi, a Chinese electric vehicle and robot company, with Galbot, a leading Chinese robot company. The robot goes around the body to check that cables and wheels are properly installed. Currently, it is being put into production lines of various companies, including Chinese electric vehicle brand Zicker. [Woosh = correspondent Song Kwang-seop]](https://wimg.mk.co.kr/news/cms/202508/25/news-p.v1.20250824.749242b3e74d4471a138c3c0717bbe5e_P1.png)

Commercialization of humanoid robots is rapidly taking place in Chinese manufacturing sites. Recently, Purin Palace, a Chinese auto parts company, installed about 100 humanoid robots of Agibot, a Chinese robot company, at its factory. It is known that it is the largest case ever put into the actual production line. The total purchase size has not been disclosed, but it is said to amount to tens of millions of yuan. «Robots are performing better than expected in the production line,» a Purin Palace official said. «This allows workers to focus on more valuable work.»

Agibot also won a 124 million yuan (about 24 billion won) order for humanoid robots from China Mobile, a state-run news agency, last month. Agibot is a company recently invested by LG Electronics and Mirae Asset and has announced plans to supply 100,000 humanoid robots over the next three years. Ubitech also signed a robot supply contract with Chinese carmaker Dongfeng Motor Co. and electric car parts maker Mii Motor Co. last month.

The growth of the industrial robot market in China is gradually accelerating. According to China’s National Bureau of Statistics, the production of industrial robots in the first half of this year was 369,000, up 35.6% from the same period last year. It has already exceeded its annual figure (366,000 units) in 2021, and if the current trend continues, total production is expected to exceed at least 740,000 units this year. This is more than three times the size of 2020 (237,000 units). It was 443,000 units in 2022, 429,000 units in 2023, and 556,000 units in 2024.

[Woosh = correspondent Song Kwang-seop]