Tesla is now requiring its suppliers to exclude China-made components in the manufacturing of its cars in the United States, the news agency Reuters reported quoting Wall Street Journal (WSJ). Tech billionaire Elon Musk-led automaker and its suppliers have already replaced some China-made components and aim to switch all other components to those made outside of China in the next year or two, the report said, citing people familiar with the situation.

Pricing Strategy Complications

Executives have struggled with fluctuating tariffs in the US-China trade dispute, complicating pricing strategies, the WSJ added.

Tesla has been increasing North American sourcing for its US factories for two years amid tariff threats, Reuters had reported in April.

China Sales Sees Recent Decline

Earlier this month, data from the China Passenger Car Association showed that Tesla’s China-made electric vehicle sales fell 9.9 per cent to 61,497 units in October from a year earlier, reversing a 2.8 per cent increase in September.

Output of the Model 3 and Model Y from its Shanghai plant, including exports, dropped 32.3 per cent from September.

Tensions between the two countries have left car executives in triage mode throughout 2025. US President Donald Trump’s on-again, off-again tariffs and bouts of industry panic over potential rare-earth bottlenecks and chip shortages have auto companies rethinking their reliance on China, an important source of parts and raw materials.

General Motors this week told thousands of suppliers to remove China-made components from their supply chains.

Strategic Implications For Tesla Operations

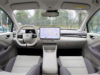

The directive represents a significant strategic shift for Tesla, which has maintained complex supply chain relationships with Chinese manufacturers for various vehicle components. The company’s Shanghai Gigafactory serves as a crucial manufacturing hub for both domestic Chinese sales and exports to international markets, making the supply chain reconfiguration particularly complex.

Tesla’s American manufacturing facilities, including its plants in Fremont, California, and Austin, Texas, will be primarily affected by the new sourcing requirements. The transition away from Chinese-made components necessitates identification of alternative suppliers capable of meeting Tesla’s quality standards, production volumes, and cost targets.

Supply Chain Diversification

The one-to-two-year timeframe for complete transition indicates both the complexity of untangling established supply relationships and the urgency driving the initiative. Some components may prove more challenging to source from non-Chinese suppliers, particularly specialized electronics, battery components, and processed materials where Chinese manufacturers have achieved significant market dominance.

Automotive Sector Faces Supply Chain Restructuring

Tesla’s announcement follows a broader pattern across the American automotive industry, with multiple manufacturers reassessing their Chinese supply chain dependencies. The combination of geopolitical tensions, tariff unpredictability, and concerns about supply security has prompted a fundamental rethinking of sourcing strategies that developed over decades of globalisation.

The shift away from Chinese components could result in increased manufacturing costs in the short term, though manufacturers hope that developing alternative supply chains will provide greater stability and potentially offset higher component costs through reduced tariff exposure and supply chain risk mitigation.

Market Impact And Future Outlook

The supply chain reconfiguration occurs against a backdrop of declining Tesla sales performance in China, the world’s largest electric vehicle market. The simultaneous challenges of restructuring American manufacturing supply chains whilst navigating a softening Chinese market position present significant operational and strategic challenges for the automaker.

Industry analysts suggest that Tesla’s deep integration with Chinese manufacturing — both as a production location and component source — makes the transition particularly consequential compared to traditional automakers with less exposure to Chinese supply chains.