Automaker aims to replace all Chinese components within two years as trade tensions reshape global supply chains.

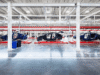

Tesla has issued a sweeping directive to its suppliers requiring them to eliminate China made components from vehicles manufactured at American facilities, according to reports emerging Friday. The mandate represents a significant acceleration of the electric vehicle maker’s efforts to disentangle its domestic production from Chinese supply chains amid escalating trade tensions between Washington and Beijing.

The Elon Musk led automaker has already begun replacing certain Chinese sourced parts and expects to complete the transition away from all remaining China made components within the next one to two years. This timeline suggests an aggressive restructuring of supply relationships that have been built over years of global manufacturing integration.

Tesla expands North American sourcing

The shift marks an intensification of efforts that began roughly two years ago when Tesla started increasing North American sourcing for its United States factories. That earlier initiative came as tariff threats loomed over cross Pacific trade, prompting the company to begin evaluating alternatives to its established procurement patterns. The latest requirements take that strategy to its logical conclusion by mandating complete elimination rather than gradual reduction.

Executives across the automotive industry have struggled to navigate fluctuating tariff policies that have complicated pricing strategies and long term planning. The unpredictability of trade policy under the current administration has forced companies to maintain contingency plans and alternative sourcing options, driving up costs and operational complexity.

For Tesla, the challenge involves balancing its significant manufacturing presence in China against its domestic production needs. The company operates a major facility in Shanghai that produces both vehicles for the Chinese market and exports to other regions. Recent data showed that China made Tesla electric vehicle sales declined nearly 10 percent in October compared to the previous year, reversing a modest gain recorded in September.

Production challenges mount in Shanghai

Output from the Shanghai plant, which manufactures the Model 3 and Model Y, dropped more than 32 percent from September to October. This steep decline reflects both softening demand in the Chinese market and broader complications in the company’s Asian operations. The facility has been central to Tesla’s global strategy, serving as a lower cost manufacturing hub that helps the company compete on price.

The sourcing mandate creates tension with this production model. While the Shanghai plant will continue operating, the requirement to exclude Chinese components from American built vehicles necessitates maintaining separate supply chains for different markets. This segmentation increases complexity and potentially reduces economies of scale that come from unified global sourcing.

Industry wide retreat from China dependence

Tesla’s directive arrives amid a broader automotive industry reassessment of Chinese supply chain dependence. General Motors recently instructed thousands of suppliers to remove China made components from their networks, signaling that the pivot away from Chinese sourcing extends beyond a single manufacturer’s strategy.

Throughout 2025, tensions between the United States and China have left automotive executives in what industry observers describe as triage mode. President Trump’s inconsistent tariff, coupled with periodic concerns about rare earth element access and semiconductor availability, have prompted major manufacturers to reconsider their reliance on Chinese parts and raw materials.

China remains a crucial source of components and materials for global automotive production. The country dominates production of battery materials, rare earth elements used in electric motors, and numerous electronic components essential to modern vehicles. Shifting away from these established supply chains requires identifying alternative sources, qualifying new suppliers, and potentially accepting higher costs.

The transition presents particular challenges for electric vehicle manufacturers like Tesla, which depend heavily on battery technology where Chinese companies hold significant advantages in both cost and scale. Finding non Chinese suppliers capable of meeting quality and volume requirements while remaining price competitive will test the feasibility of complete supply chain separation.

As automakers navigate these changes, the ultimate impact on vehicle costs and production timelines remains uncertain. The coming months will reveal whether the industry can successfully execute this geographic reorientation without significant disruptions.