Support CleanTechnica’s work through a Substack subscription or on Stripe.

As the company with the highest EV patent count files dozens of patent applications every day, it can be difficult to keep up with BYD. However, a few patents published last week show different approaches to recovering energy from suspension damping, which we find quite interesting. These inventions have also already gained some attention in Chinese media and on social media. However, BYD appears to be taking a couple of different directions on these, as they apparently haven’t settled on one path yet. Since CleanTechnica readers tend to be a smart bunch who like to nerd out on this type of stuff, I was wondering: which direction do you think would work best?

For a little background: dampers or shock absorbers absorb energy from the wheels when hitting bumps, dips, and other road irregularities, while minimizing the transfer of energy to the vehicle’s body, thus reducing NVH (noise, vibration and harshness). They also work to control wheel motion to keep the tire from bouncing up and losing grip on the road. And they control the car’s weight transfer in pitch, roll, and dive while accelerating, turning, and braking. To provide this function, the typical damper uses a piston with an arrangement of holes and shims (aka valving) that restrict flow of a hydraulic fluid, kept under pressure to prevent cavitation. This creates viscous friction to convert energy in the motion of the suspension into heat.

However, passive dampers have limitations in how they control suspension motion. As a modification, adaptive dampers either run a current through a magnetorheological fluid that changes its viscosity or change the valving, increasing or decreasing the damping force. To take it a step further, traditional active suspensions provide the benefit of dynamically managing the suspension motion for superior control, at the cost of added energy consumption.

However, the newly published patents focus on actively capturing the energy from suspension motion. Depending on the design and implementation, these systems could increase net vehicle efficiency versus a passive damper, or at least compensate for the energy used to better control the suspension. But there are significant differences.

To Screw?

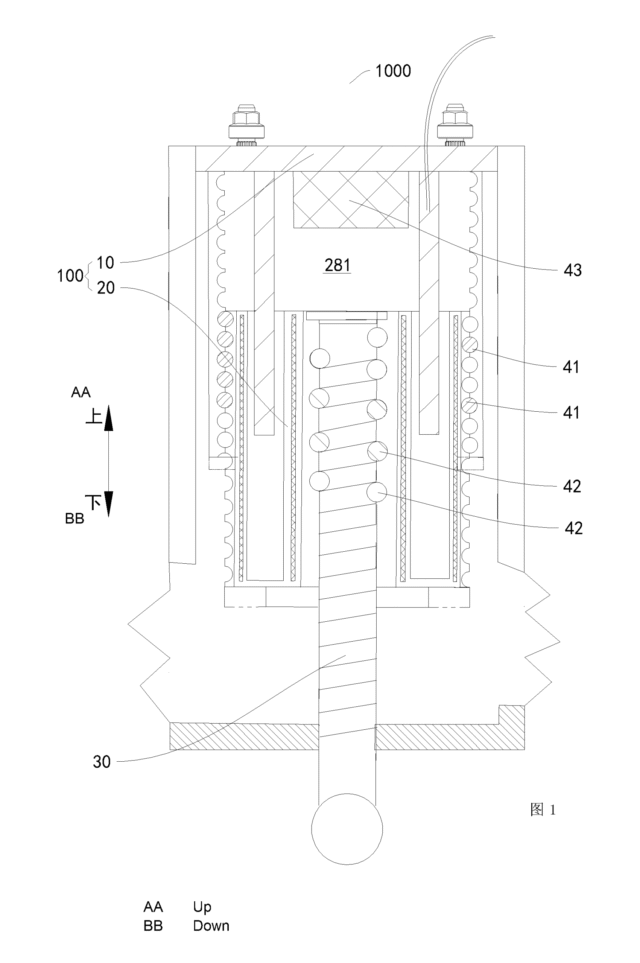

The first option, “WO2025185148 – VEHICLE VIBRATION REDUCTION ASSEMBLY, SUSPENSION SYSTEM, AND VEHICLE,” nests an intermediate fitting (20) between an inner shaft (30) and outer housing (10) interfacing between the three parts with a ball screw, a type of lead screw that uses ball bearings in the grooves of the screw to reduce friction. The alternating thread orientation allows for the inner shaft and outer housing to not rotate as the assembly telescopes in and out, while the intermediate fitting spins in between them. The ring-shaped intermediate member has a deep groove with permanent magnets on each side, creating a rotor. A coil attached to the upper housing then sits within that groove to form a motor/generator. As the intermediate member/rotor also moves up and down as it spins, positioning the coil deeper into the gap as the suspension compresses, the motor/generator would potentially increase in power as the suspension compresses. A modification on the system uses two of these motors in mirror image, connected at the shaft. In both cases, one side connects to the chassis, and the other side connects to the suspension arm.

Due to the telescoping nature of the damper, the overall package could be shorter for the same travel. This could be beneficial for lower hoods or other places where vertical space is limited. However, I would expect the overall package to be wider than a traditional damper. As the suspension is controlled by electricity and generates electricity to be stored by the battery, relatively little other hardware is needed outside of the suspension. While more complex than a traditional passive damper, the integration of the motor into the damper is relatively simple mechanically. The intermediate member/rotor is the only moving part, other than the vertical motion of the shaft. While a screw is one of the oldest inventions, it is somewhat untried in vehicle suspensions, and there are no off-the-shelf parts. That newness will likely require a lot of testing and validation.

Or to Pump?

The second option in the patents, ”WO2025185171 – HYDRAULIC SUSPENSION SYSTEM” and related “WO2025185172 – HYDRAULIC SUSPENSION SYSTEM AND CONTROL METHOD,” replace the traditional passive damper with a hydraulic cylinder (100). That hydraulic cylinder transfers energy from suspension movement to pump hydraulic fluid. That fluid then pushes through an array of valves and solenoids to (15) accumulators that store energy as pressure, or it sends the fluid through a motor/generator (7) that converts the energy into electricity.

The hydraulic cylinder is likely even narrower than a traditional damper, creating packaging advantages at the suspension mounting point. The other components can then be moved almost anywhere on the chassis, providing packaging flexibility. Some are speculating that this would make it well suited for a skateboard-style chassis. However, the accumulators and motors are likely to take up a significant amount of space. And, while mechanically storing energy as pressure provides another path to energy recovery, it makes the overall system more complex compared to just converting it to electricity. Overall, the system is more complex than the screw design, especially when considering that the motor/generator, solenoids, valves, accumulators, etc., are not detailed in the drawings. However, hydraulics in suspension applications are well established.

Which Would You Choose?

If you are interested in the technology, it is worthwhile digging into the patents to get a deeper understanding of the details and wrap your head around it. Patent drawings are also oversimplified, and it would be interesting to explore the implementation in the products being developed. However, even on a superficial level, both directions seem to have advantages and disadvantages. While some technologies, such as chassis sensors and control software, might be able to be adapted from one to the other, there are fundamental differences.

However, if you were in charge, which would you pursue? Would you use a different system for a different type of vehicle? Would you develop both and see which one wins in the real world?

Typically, these technologies are first applied to premium vehicles and then trickle down into more accessible models. In the case of BYD, that “trickle” tends to be more of a stream. If you were to have one or the other available for your daily driver, would you find recovering energy from the suspension while actively improving control and reducing NVH compelling? Would you pay more for it? Which direction would you pick for your own car?

Sign up for CleanTechnica’s Weekly Substack for Zach and Scott’s in-depth analyses and high level summaries, sign up for our daily newsletter, and follow us on Google News!

Have a tip for CleanTechnica? Want to advertise? Want to suggest a guest for our CleanTech Talk podcast? Contact us here.

Sign up for our daily newsletter for 15 new cleantech stories a day. Or sign up for our weekly one on top stories of the week if daily is too frequent.

CleanTechnica uses affiliate links. See our policy here.

CleanTechnica’s Comment Policy