Researchers at the University of Michigan have developed a machine-learning system capable of predicting battery lifespan after only around 50 charge–discharge cycles, potentially reducing testing time and energy consumption by up to 95%, according to a study published in Nature, as reported by IT-home.

Traditional battery validation typically requires hundreds or thousands of cycles to estimate durability, often taking months or years. The new approach combines early-stage experimental data with physics-based modelling to forecast long-term degradation, significantly accelerating battery development workflows.

The system was developed by a research team led by Assistant Professor Ziyou Song and doctoral researcher Jiawei Zhang. It comprises multiple AI components that select battery designs, analyse experimental data, and predict long-term performance. The researchers describe the framework as an “agentic” AI architecture that iteratively improves predictions by integrating experimental results with physical models.

The project was supported by Farasis Energy, which provided real-world data and pouch battery samples to validate the model. Farasis Energy is a lithium-ion battery manufacturer with major manufacturing operations in China and a global footprint spanning the United States, Europe and Turkey. Its headquarters and key production bases are located in Ganzhou and other Chinese cities, with large-scale capacity under development.

Farasis is deeply integrated into China’s electric vehicle supply chain, supplying batteries to automakers including Geely, GAC, FAW, Dongfeng and Great Wall Motor. The company has also partnered with global brands such as Mercedes-Benz and has ranked among the leading global pouch-cell suppliers.

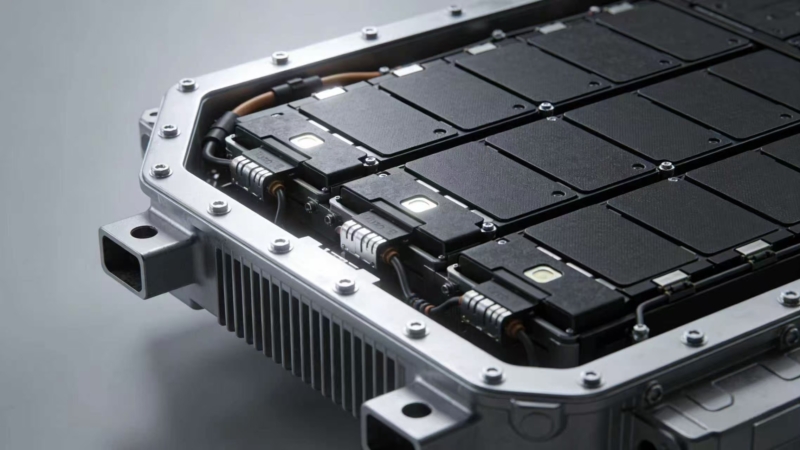

According to the research team, the AI system can generalise across different battery formats, from cylindrical cells used in consumer electronics to large-format pouch cells used in electric vehicles. Even when trained on cylindrical battery data, the model successfully predicted the lifespan of pouch batteries supplied by Farasis.

Beyond lifespan prediction, the researchers are exploring extensions of the framework to estimate safety limits, optimise charging strategies and identify promising materials for next-generation lithium-ion batteries. Farasis itself is developing advanced battery technologies, including semi-solid and solid-state cells, which have been recognised among China’s leading projects in the field.

The development highlights how artificial intelligence is increasingly intersecting with the global battery industry, in which Chinese manufacturers play a central role in production scale, technology development, and electric vehicle supply chains.

Follow us for ev updates