The third China solid-state battery innovation summit in Beijing, earlier this month, highlighted industry-wide challenges, with Professor Xia Dingguo of Peking University noting that energy density, primarily determined by the cathode, remains critical, and that cathode innovation, rather than electrolyte breakthroughs, is key to moving solid-state batteries from laboratories to commercial production, as Autohome reports.

The resurgence of interest in solid-state batteries is linked to two main factors: substantial improvements in overall research capabilities since the 1990s, and the growing demand for higher energy density, safety, and material optimisation in EV applications. Solid-state batteries are expected to achieve high energy density, safety, long life, and low cost, but without breakthroughs in cathode technology, their industrial significance is limited.

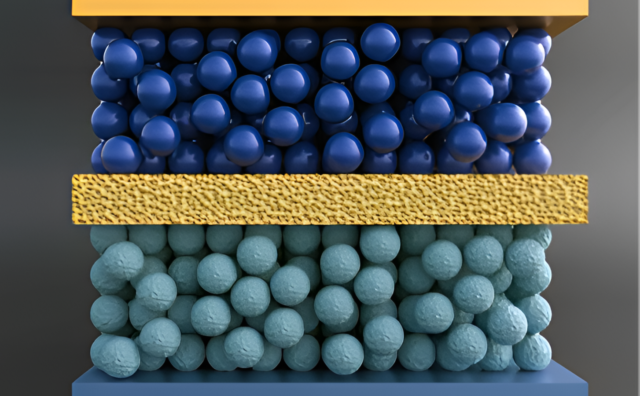

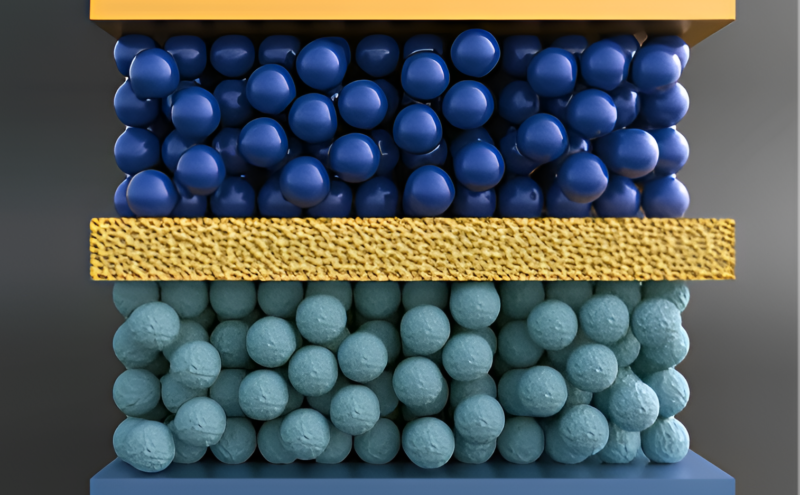

Current challenges centre on interface stability and material compatibility. Experiments with high-nickel cathodes demonstrate improved thermal stability but retain safety risks under high current or voltage conditions due to local polarisation, formation of a high-impedance layer, and eventual performance degradation. Fluorine doping can temporarily stabilise cycling, but degradation accelerates beyond around 125 cycles. Crystalline cathode materials are anisotropic, and even small volume changes can concentrate stress at interfaces, limiting cycle life.

Material compatibility further constrains commercial adoption. Different solid electrolytes, including chlorides, sulfides, and oxides, exhibit varying moduli and interface behaviour. Oxides are too rigid; sulfides and chlorides often require applied pressure, which complicates manufacturability. Addressing these challenges will require low-modulus, interface-friendly electrolytes or optimised polymers capable of broad voltage windows and high conductivity.

China’s leading battery manufacturers, including CATL, BYD, and Eve Energy, have begun integrated development of cathode and electrolyte systems, creating patent protections while optimising cell performance. Advances in dry electrodes, co-sintering, and cold sintering are further enabling scalable production and reducing reliance on complex coating processes.

Looking forward, the industry is expected to pursue diverse paths for different applications: high-end EVs with polymer electrolytes and high-nickel or lithium-rich cathodes; mass-market EVs focusing on LiFePO4 systems, emphasising safety and cost; and specialised applications exploring sulfide electrolytes paired with sulfur cathodes.

The summit concluded that cathode material innovation is the “bull’s nose” of industrial solid-state batteries. Electrolytes remain important, but energy density, cost, and stability fundamentally depend on cathode development. The future will require dual-track progress in material innovation and engineering manufacturing to ensure China’s leadership in the global solid-state battery sector.

Follow us for ev updates