China has completed its first large-capacity all-solid-state battery production line, according to Chinese state media. The facility, built by GAC Group, is currently producing 60 Ah+ vehicle-grade cells on a small-batch test basis. These cells are projected to allow electric vehicles with current 500 km ranges to exceed 1,000 km once integrated. Mass production is planned for 2027-2030.

The term “60 Ah+” refers to the capacity of each battery cell in ampere-hours (Ah). A 60 Ah cell can theoretically supply 60 amperes for 1 hour before discharging completely. Higher Ah per cell generally means more energy storage, which can translate into a longer driving range when multiple cells are assembled into a battery pack.

All-solid-state batteries use solid electrolytes instead of liquid ones, which improves thermal stability and safety. GAC’s production line reportedly achieves an areal capacity of up to 7.7 mAh/cm², compared with less than five mAh/cm² in traditional “wet” lithium-ion manufacturing.

GAC’s research director, Qi Hongzhong, said the energy density of the new solid-state cells is nearly double that of conventional batteries. Vehicles currently capable of 500 km (~310 miles) on a single charge could potentially reach more than 1,000 km (~620 miles) with these cells.

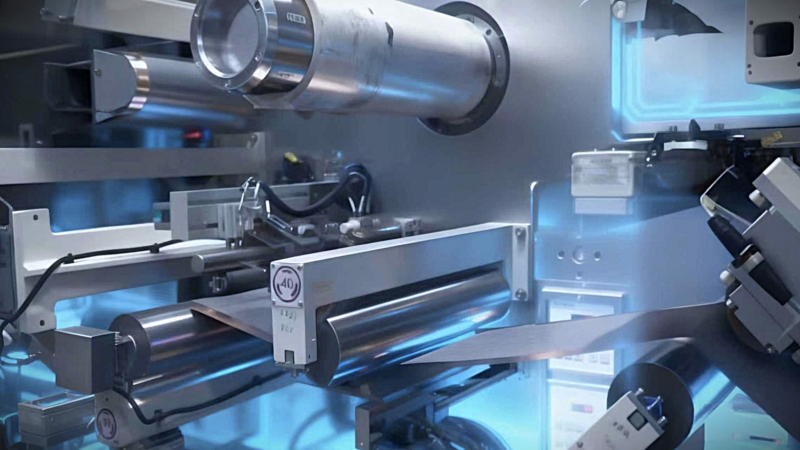

The company is using a “dry” anode production process that combines slurry mixing, coating, and rolling into a single step. This technique reportedly improves manufacturing efficiency and reduces energy consumption. The solid electrolyte can tolerate higher temperatures than liquid electrolytes, reportedly withstanding 300–400 °C compared with approximately 200 °C for conventional batteries.

Small-batch vehicle integration tests are planned for 2026, with a gradual ramp-up to mass production between 2027 and 2030. While the milestone represents a significant technical achievement, commercialisation will depend on investment, reliable supply of solid electrolyte materials, and validation of long-term performance and safety in vehicles.

Editor’s comment:

Globally, commercialisation of all-solid-state batteries remains limited, with several automotive and battery manufacturers exploring the technology. GAC’s production line positions the company among the first in China to have industrial-scale capability for large-format all-solid-state cells. The pace of scale-up and cost competitiveness will determine the technology’s impact on the EV market.

Follow us for ev updates