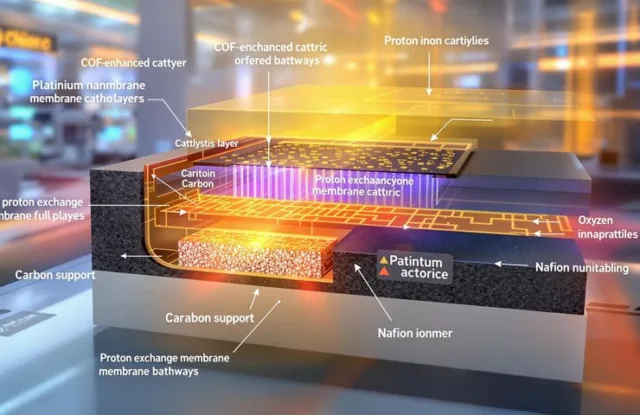

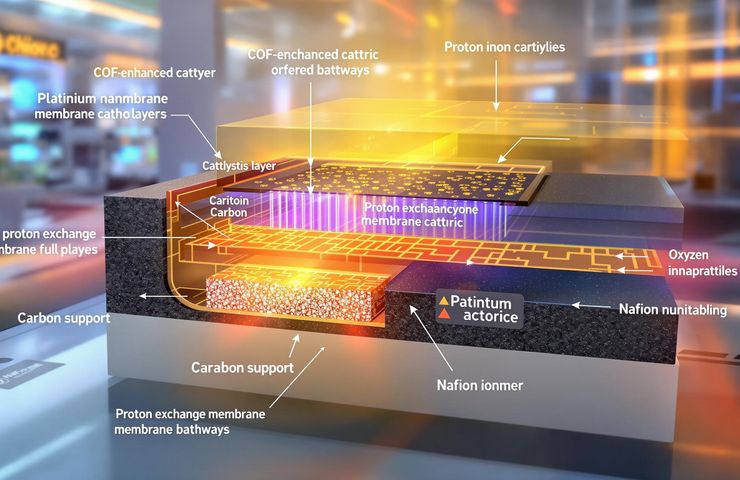

Chinese researchers have just raised the bar in fuel cell technology. A team has developed a smart new catalyst layer that slashes oxygen transport resistance and minimizes power loss in proton exchange membrane fuel cells (PEMFCs). The secret? Tweaking the interface with something called triazine-based covalent organic frameworks (COFs). The result: a dramatic 38% drop in oxygen resistance and a stellar power density of 1.55 W/cm² — all while using just 0.05 mg_Pt/cm² of platinum. That’s an ultra-low loading with performance that turns heads.

The research, now peer-reviewed and published in Angewandte Chemie, was carried out by a group of standout scientists from China, including Prof. Min Wang, Dr. Quanbin Dai, Yilin Wang, Enyang Sun, Prof. Mingbo Wu, and Prof. Zhongtao Li. This discovery could change the way we think about catalyst layers — not just in fuel cells, but across a whole range of electrochemical systems where oxygen supply tends to bottleneck performance.

A Fresh Answer to a Lingering Problem

Since the 1960s, PEMFCs have battled a nagging issue: poor oxygen movement at what’s called the triple-phase boundary. That limitation gets worse thanks to ionomer clumping and material shortfalls — and it really kicks in just when these systems need to deliver at high current. That’s a big barrier for commercial use.

This is where the new COF material steps in:

- It reshapes the cathode catalyst layer through clever interactions with Nafion’s sulfonate groups.

- It creates a mesh of highly organized mesopores, helping oxygen get to the platinum where it’s needed.

- It boosts the bang for your buck — or in this case, boosts platinum utility even with minuscule amounts.

In the past, reaching this kind of performance meant stacking expensive membrane-electrode assemblies (MEAs) or oversizing the system — both major cost drivers. But now, there’s a real shot at hitting both high performance and affordability.

Strategic Wins and Climate Progress

This leap in performance ties in perfectly with China’s hydrogen roadmap. Hydrogen fuel — especially for transportation and stationary backup — plays a big role in China’s plan to hit net-zero emissions by 2060. Fuel cell vehicle rollouts are already in motion, and cutting down platinum usage is key to making them viable long-term.

With a stunning 1.3x boost in power density compared to common designs using similar precious metal loadings, the economics finally start tipping in favor of hydrogen fuel cells. On top of that, replacing a chunk of platinum with COF-based architecture could ease dependence on rare earth materials — which helps reduce risk across global supply chains.

Beyond Just Fuel Cells

The benefits of this COF engineering don’t stop at PEMFCs. This fine-tuned interface approach could also make waves in electrolyzers, especially for high-resistance oxygen evolution reactions on the anode side. And that’s just one path. The concept opens doors for smarter, localized catalyst strategies in areas like ammonia production and electrochemical CO₂ reduction — both of which suffer from gas transport bottlenecks.

Better oxygen movement also means lighter demands on the system itself. That could cut back the need for things like extra compression or humidification — a big win for operations in hot climates or off-grid setups.

“This kind of nano-confined interface approach represents a new engineering paradigm,” said one materials scientist not involved in the study. “It’s about making the catalyst, membrane, and gas flow all work in sync — not in conflict.”

Where It’s Headed

There’s still one major question: can this trick scale? The paper doesn’t dive into how this technique would handle real-life, large-format MEAs or how it survives through punishing stress cycles. But industry eyes are already locked in — especially from cell stack builders eager for flexibility and performance without leaning too heavily on scarce metals.

With catalyst innovation moving fast and this breakthrough sitting squarely in line with global hydrogen ambitions, we might see early commercial pilots within two to three years — particularly in Asia and Europe, where hydrogen fuel cells are starting to power trucks, buses, and more.

Bottom line? This discovery moves the needle. It brings us one step closer to low-cost, long-lasting, high-performance PEMFCs — not just as a lab dream, but as a real, scalable solution for cleaner transport, energy backup, and more.

Spread the love

Source: hydrogenfuelnews.com