Discussion of the safety of solid-state batteries (SSBs) intensified in China in December 2025, as industry experts and researchers increasingly cautioned against characterising the technology as inherently or absolutely safe, according to Sina. While SSBs remain a focus of next-generation lithium battery development, recent commentary highlights unresolved safety risks and challenges to large-scale deployment.

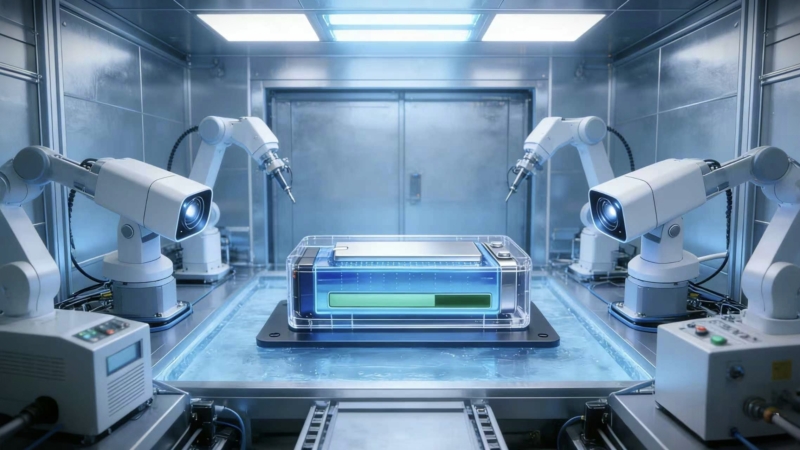

Solid-state batteries replace conventional liquid electrolytes with solid electrolytes and are expected to offer higher energy density and a wider operating safety margin. These characteristics have driven strong investment interest in 2025, alongside expectations that China’s 2026 national safety standard for power batteries, effective July 1, requires new batteries to withstand specified abuse tests without catching fire or exploding within 5 minutes. Industry observers note that the standard does not exclusively apply to SSBs and does not eliminate fundamental lithium battery safety risks.

At the 2025 World Power Battery Conference, academics emphasised that SSBs remain energy-dense electrochemical systems and cannot be considered free of thermal runaway risk. Researchers noted that lithium metal, commonly used in SSB designs, remains highly reactive. Experimental research cited by analysts indicates that lithium metal can react directly with cathode materials in the absence of oxygen, thereby triggering aluminothermic reactions at temperatures up to 2,500 °C under extreme conditions. Such reactions may occur even in fully discharged batteries.

Experts also highlighted that lithium dendrite formation, a known failure mechanism in liquid lithium-ion batteries, has not been eliminated in SSBs. While solid electrolytes can theoretically suppress dendrite penetration, real-world materials may contain microscopic gaps or grain boundaries that allow dendrites to propagate, potentially causing internal short circuits. In addition, many SSB prototypes rely on high-nickel cathodes and silicon-based anodes to achieve higher specific energy, but these materials are associated with increased thermal instability.

Several Chinese automakers are advancing the development of SSBs, underscoring the need for thorough safety assessment. FAW Group plans to equip Hongqi vehicles with solid-state batteries by 2027, while GAC Group has begun trial production at an all-solid-state battery pilot facility for small-batch vehicle testing. Dongfeng Motor targets mass production of batteries with energy densities of approximately 350 Wh/kg by late 2026, potentially enabling EV ranges exceeding 1,000 km. SAIC Motor and Chery Automobile are also progressing prototype and pilot programs aimed at 2027 integration. These timelines highlight why experts emphasise rigorous validation of safety performance alongside commercial deployment.

Chinese analysts caution that presenting SSBs as a guaranteed solution to battery fires or explosions risks distorting technical reality. Conventional liquid lithium-ion batteries continue to see safety-related improvements through flame-retardant electrolytes, electrode surface coatings, and high-temperature-tolerant cell designs, extending their viability in applications such as stationary energy storage. Industry consensus increasingly points toward coexistence rather than full replacement: SSBs may suit applications prioritising high energy density and strict safety margins, while liquid lithium-ion batteries remain competitive in cost-sensitive and mature deployment scenarios.

Follow us for ev updates